PX is a main monomer of polyester fiber and PET plastics, with an annual demand of 49 million ton worldwide. If all PX from petroleum now is tuned to be made from CO2, 0.16 billion ton CO2 will be fixed every year.

We aim to commercialize this CO2-to-PX novel technology before 2028 with the aid of NEDO, Japanese government. The consortium includes Tsubaki lab. at Univ. Toyama, Nippon Steel Co., Nippon Steel Engineering Co., HighChem Co., Chiyoda Co., Mitsubishi Co..

Tsubaki et al invented the direct synthesis technology of para-xylene (PX)/PET from CO2 for the first time in the world and it is now under scale-up. The zero-carbon PX/PET produced in pilot plant in Yokohama city of Chiyoda Corp. is now used to fabricate the zero-carbon uniform with the highly-ranked fashion brand " The North Face ", by the Toyama-initiated Goldwin Company who produces and sells this brand worldwide. Now this carbon-neutral PET uniform is commercially being sold for the first time in the world. Especially, this zero-carbon uniform is adopted as official uniform for Japan team of sport climbing in Paris Olympic Games 2024. Meanwhile, USA team, Korea team and Austria team will also use this uniform in sport climbing contest of Paris Olympic Games started on August 5, 2024 at PM5, Japan time.

See Figures 1-5 below.

https://about.goldwin.co.jp/news/page-36620

Figure 1.Zero-carbon PET fiber uniform, the first time in the world, for Japan sport climbing team to Paris Olympic Games 2024

Figure 2.Zero-carbon PET-based uniform for Japan, USA, Korea, Austria teams to Paris Olympic Games 2024, sport climbing contest.

Figure 3.The first case in the world, zero-carbon uniform by The North Face produced for Japan sport climbing team to Paris Olympic Games 2024

Figure 4.Global partners in this new carbon-neutral business

Figure 5.The new carbon-neutral technology initiated from Tsubaki lab and Japan; I considered this idea in 2011.

Now the zero-carbon PET uniform, including kid style, is being sold at the Tokyo-Harajuku shop, Tokyo-Ebisu Shop, Osaka Grand Front shop etc. of The North Face. Net shopping is also available as the link below. See the Figures 6-9.

https://www.goldwin.co.jp/tnf/special/wallhuman/2024/article/international-collection-for-2024/

Figure 6. Goldwin Co. sells the carbon-neutral products for the first time in the world.

Figure 7.NEDO X SNS report

Figure 8.Report by Nikkei (Japan Economy Newspaper)

Figure 9.Press-release by Goldwin Co.

Related papers:

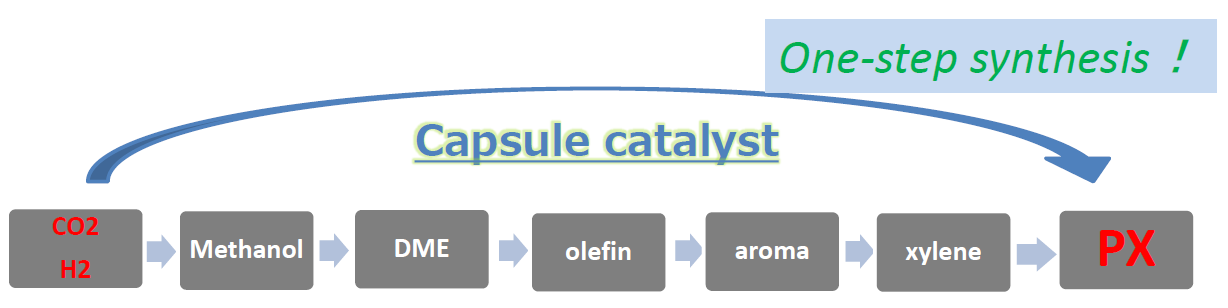

Chemical Science, 2017 isyngas CO+H2 PX jZn-Cr-O/ZnZSM5@S-1 capsule catalyst

Chemistry - A European Journal, 2019 iCO2 PX catalyst j

ACS Catalysis, 2019 iCO2 PX jCrOx/HZSM5@S-1 capsule catalyst

Other related papers:

CO2 to gasoline by capsule catalyst, Catal. Sci. Tech. 2019, ChemComm 2016

CO2 to diesel, ACS Sustainable, Chem. Eng., 2019

CO2 to LPG by capsule catalyst, ChemSusChem, 2020

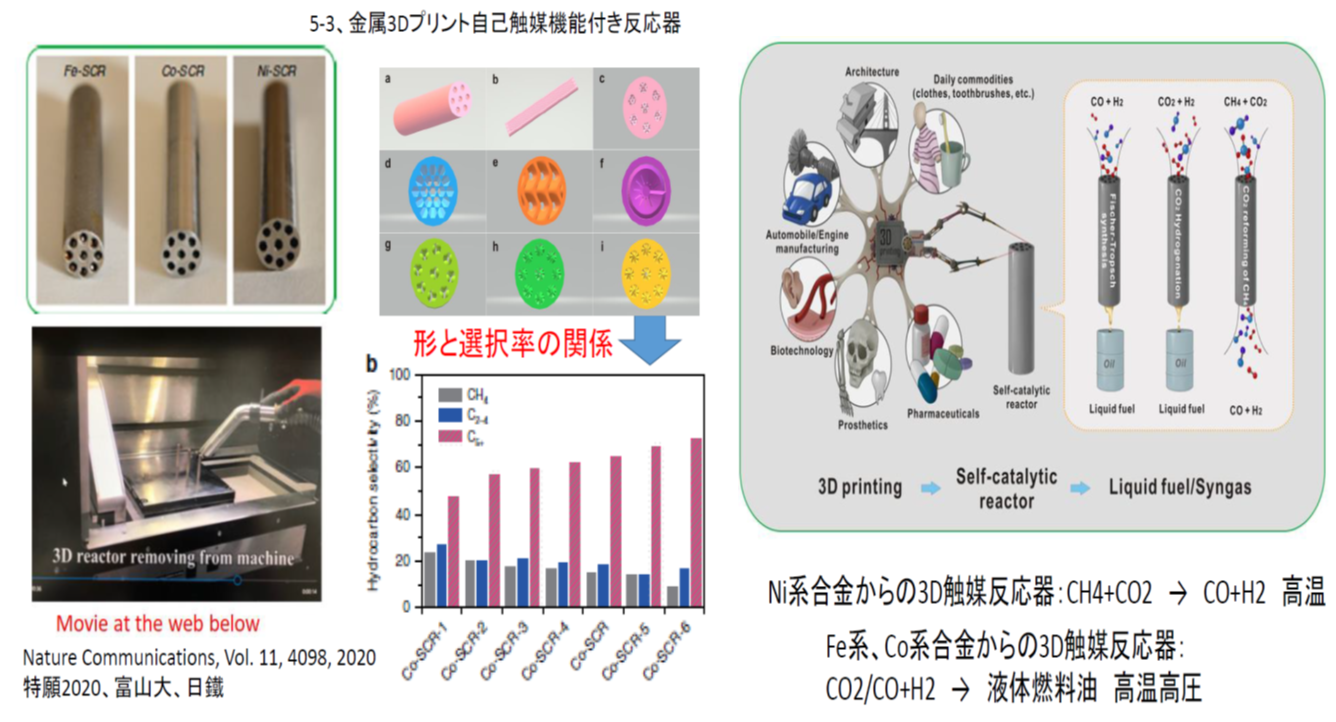

CO2+methane to syngas (CO+H2), Chemical Science, 2019

CO2 to olefins, ChemComm, 2020

CO2 to aromatics, App. Catal. B, 2020